Unveiling the Power of Laser Cleaning Machines in Auto Industry: Revolutionizing Surface Restoration

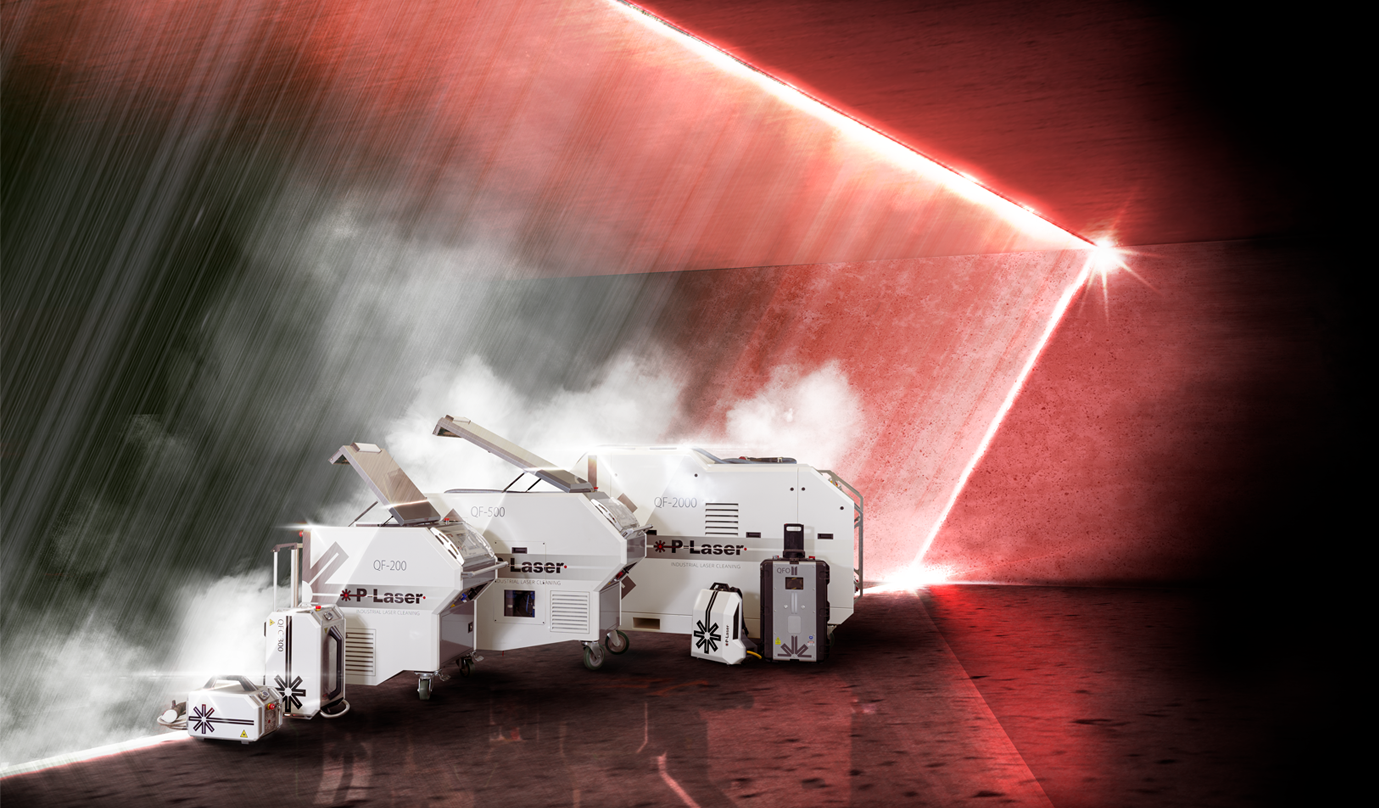

The power of laser cleaning machines has revolutionized surface restoration, enabling businesses to achieve unprecedented levels of cleanliness and efficiency. As a result, many industries have embraced this new technology due to its ease of use and cost-effectiveness.

From automotive repair shops to construction sites, laser cleaning machines are becoming an essential part of any company’s toolbox. In this article, we will explore the technology behind these powerful machines and how they can benefit your business.

Let us take a closer look at the fascinating world of laser cleaning!

Introducing Laser Cleaning Machines: A Revolutionary Way to Restore Surfaces

The introduction of laser cleaning machines has revolutionized the world of surface restoration. Utilizing cutting-edge technology, these machines offer a powerful and efficient way to eliminate dirt, dust, oils, and other contaminants from any kind of material or substrate.

Not only does this advanced process quickly remove stubborn stains without damaging surfaces, but it also leaves them looking like new again. Whether youre working on restoring hardwood floors or removing graffiti from brick walls – there’s no job too big or small for laser cleaning machines! With their incredible power and precision, they can easily tackle even the toughest jobs in no time at all. Explore the amazing capabilities that come with introducing laser cleaning machines into your life today!

Unlocking the Potential of Laser Cleaning Technology

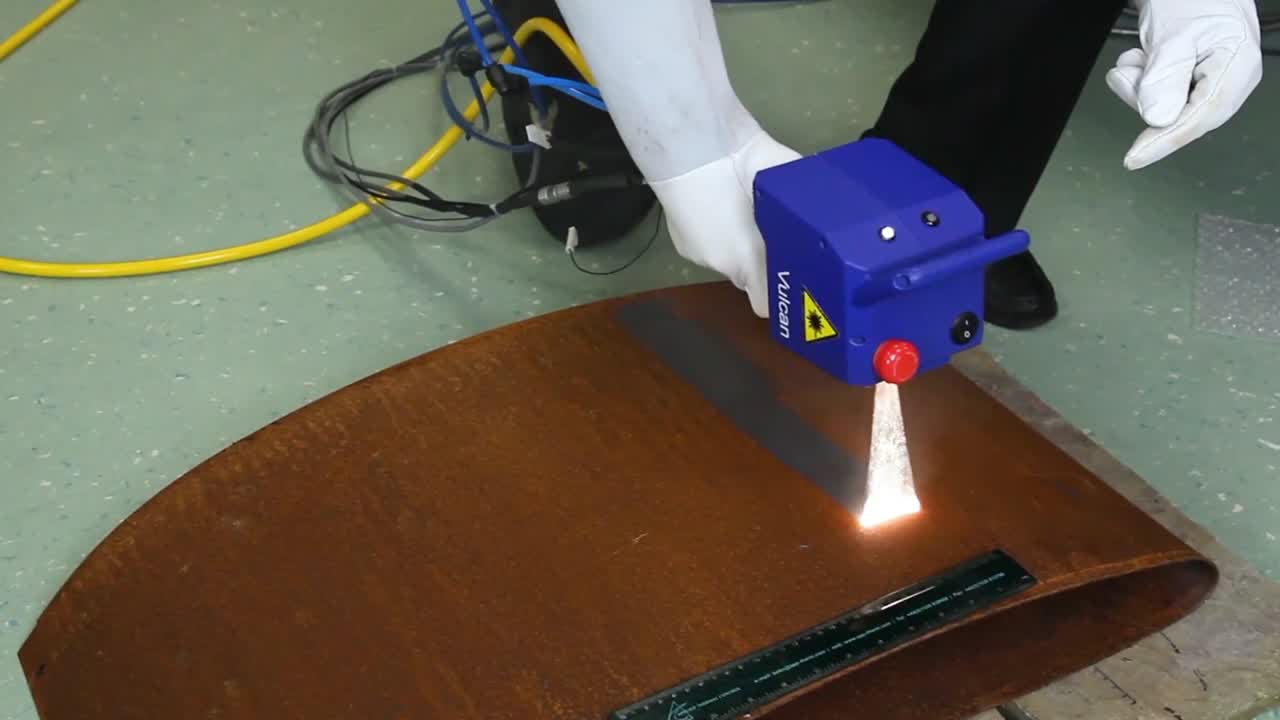

Laser cleaning machines are capable of performing complex surface restoration tasks in a fraction of the time traditional methods require. Through the application and manipulation of laser technology, these powerful machines can unlock their true potential as an innovative and efficient way to clean surfaces safely and with precision.

The ability to customize each task’s parameters ensures that users receive results that will meet or exceed expectations; whether it is removing rust from metal or stripping paint from wood, laser-cleaning technology has become a viable option for many businesses. The advances made in recent years have expanded the possibilities for what can be done with laser cleaners, opening up new applications such as removing stubborn contaminants without damaging delicate substrates or quickly preparing materials for bonding processes.

All this makes laser-cleaning machines well-suited to tackle any number of challenging cleaning scenarios while providing consistent performance over time. These incredible devices hold considerable promise when it comes to unlocking the potential of modern surface restoration techniques – but only if used correctly.

By taking full advantage of their capabilities, anyone looking for a more effective alternative than manual methods should consider investing in one today – not just because they save time but also because they provide superior results too!

Advantages of Using Laser Cleaners for Surface Restoration

The advantages of using laser cleaners for surface restoration are numerous and far-reaching. Laser cleaning machines offer several benefits that make them a superior option to other methods such as sandblasting, abrasive cleaning, and chemical cleaning. For instance, laser cleaners remove contaminants without causing any damage to the underlying substrate material; they provide precise control over the size, depth, and shape of the cleaned area; they can be used on delicate or hard-to-reach surfaces with ease; and their operation is fast and non-intrusive.

Additionally, they require minimal maintenance costs since no consumables are needed for their operation. Furthermore, these machines have an excellent safety profile as no toxic chemicals are released during use.

With all these advantages in mind, it’s easy to see why more people are turning towards laser cleaning solutions when looking for ways to restore surfaces effectively yet safely.

Discovering New Applications with Laser Cleaners

Laser cleaning machines are revolutionizing surface restoration by offering a new way of addressing environmental and industrial problems. With the use of laser cleaners, industries have been able to discover new applications that could not be addressed in traditional cleaning methods.

Laser technology has enabled them to address difficult-to-remove contaminants such as paint, grease, oil, rust, and other types of deposits. It can also remove corrosion from metals without damaging the underlying material or substrate.

Additionally, these lasers can even clean delicate surfaces without causing any physical damage. The possibilities for using laser cleaning machines are virtually endless and companies across all sectors are beginning to explore its potential applications.

Whether it’s for automotive maintenance or aircraft engine repair – there is no limit when it comes to discovering new ways to utilize this revolutionary technology!

Laser Cleaning Machines In Car Industry

Laser cleaning machines have emerged as a game-changer in the car industry, revolutionizing surface restoration and setting new standards for efficiency and precision. With their cutting-edge technology and remarkable capabilities, these machines have transformed the way automotive surfaces are treated and rejuvenated.

In this article, we delve into the power of laser cleaning machines and explore how they are reshaping surface restoration practices within the car industry.

1. Enhancing Efficiency and Quality:

The car industry demands impeccable quality and efficiency when it comes to surface restoration. Laser cleaning machines rise to the occasion, offering an unparalleled solution.

By utilizing focused laser beams, these machines effortlessly remove contaminants, such as paint, rust, and grease, from car surfaces. The precise and controlled nature of laser cleaning ensures minimal damage to the underlying material, preserving the integrity and aesthetics of the vehicle.

2. Precision and Versatility:

One of the key advantages of laser cleaning machines in the car industry is their ability to target specific areas with utmost precision. Whether it’s intricate parts, delicate components, or hard-to-reach corners, these machines excel at removing dirt and imperfections without causing any harm.

From cleaning engine components to restoring vintage car bodies, laser cleaning machines showcase their versatility and adaptability across various automotive applications.

3. Eco-Friendly Solution:

In an era where sustainability is a growing concern, laser cleaning machines offer a greener alternative to traditional surface restoration methods. Unlike chemical solvents or abrasive techniques that generate harmful waste, laser cleaning is a non-contact, non-abrasive process that produces minimal residue.

The absence of chemicals and reduced waste make laser cleaning environmentally friendly, aligning with the car industry’s commitment to eco-conscious practices.

4. Time and Cost Savings:

Time is of the essence in the fast-paced car industry, and laser cleaning machines deliver notable time and cost savings. Their high-speed operation, coupled with their ability to handle complex surfaces, significantly reduces the cleaning and restoration process duration.

This efficiency translates into cost savings for car manufacturers, repair shops, and car owners, enabling them to optimize their operations and allocate resources more effectively.

5. The Future of Surface Restoration:

As technology continues to advance, laser cleaning machines are poised to become an integral part of the car industry’s future. With ongoing research and development, we can expect further improvements in speed, precision, and versatility.

Laser cleaning machines will continue to refine and expand their capabilities, offering even more effective and efficient solutions for surface restoration in the automotive world.

Conclusion

Laser cleaning machines have revolutionized the surface restoration process, offering a safe and efficient solution for removing contaminants from surfaces without damaging them. Laser cleaning machines provide an environmentally friendly alternative to traditional chemical-based methods and are becoming increasingly popular due to their ability to clean faster with less risk of damage or contamination.

Laser cleaning machines have revolutionized the surface restoration process, offering a safe and efficient solution for removing contaminants from surfaces without damaging them. Laser cleaning machines provide an environmentally friendly alternative to traditional chemical-based methods and are becoming increasingly popular due to their ability to clean faster with less risk of damage or contamination.

The power of laser cleaning is undeniable, and its use will continue to grow as more applications are discovered around the world. With their precision, efficiency, safety, and eco-sustainability in mind, it’s clear that laser cleaning machines are here to stay as they become essential tools for various industries looking for better options when restoring surfaces.